Battery materials recycler Redwood announced plans for new plant in South Carolina that it said would scale up to $3.5 billion investment in the next decade.

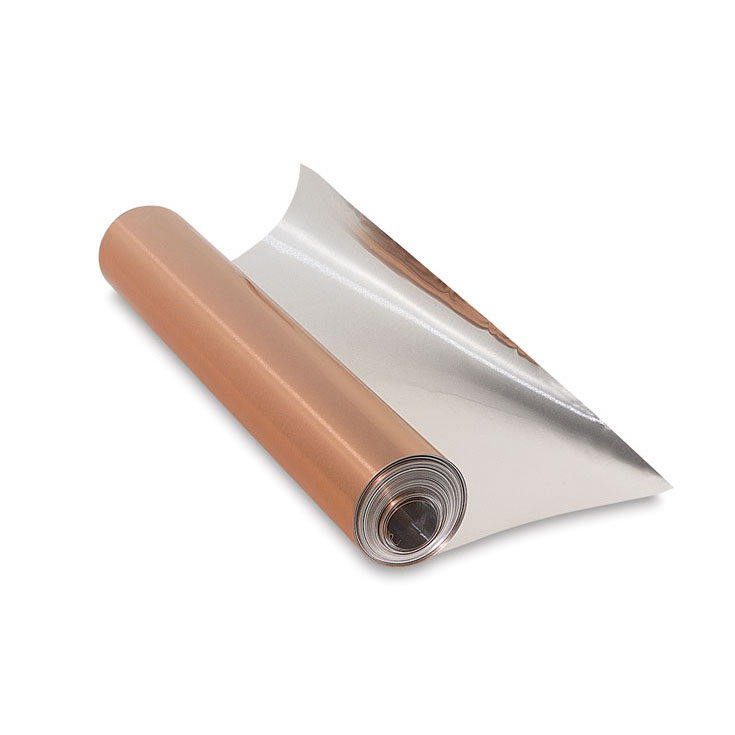

Battery recycling company Redwood Materials Inc. plans to break ground early next year on a $3.5 billion investment in an “end-to-end” battery supply chain operation over the next decade near Charleston, S.C. Adhesive Copper Tape

The plant will recycle, refine and manufacture anode and cathode components on more than 600 acres. Carson City, Nev.-based Redwood plans to have its first recycling process running by the end of 2023 and will build out downstream component manufacturing and scale it “step-by-step," the firm said in a statement.

A firm spokesperson did not disclose details on the plant's design and construction team.

Eventually the plant campus will produce 100 GWh of cathode and anode components per year, enough to power more than 1 million EVs, the company said. The site is large enough to be expanded to produce several hundred GWh to meet future demand, added Redwood. The campus, located near EV assembly plants for Volvo and Polestar, has the capacity to expand to 400 GWh, according to Reuters.

The South Carolina Commerce Dept. termed the investment the largest economic development announcement in state history.

The remanufactured battery materials will be used by U.S. battery cell manufacturers. “We take in end-of-life batteries, break them down to their basic metals like nickel, copper, cobalt, and lithium, and rebuild those metals into cathode and anode products, the most critical and expensive components in an EV,” the company said.

Producing critical battery components and recycling the materials locally “is the only way to drive down costs, emissions and the geopolitical risks,” Redwood said. Currently U.S. battery manufacturers will spend more than $150 billion overseas on these components by 2030, the company said.

The location of the planned plant, Ridgefield, S.C., is in what the company called “America’s Battery Belt,” from Michigan to Georgia where hundreds of GWh per year of battery cell production capacity will be built.

The Port of Charleston also is key to its site selection as Redwood scales production. “With increasing demand for lithium-ion batteries, the ability to import raw materials, which we will also be able to refine on this site, presents a significant advantage,” it said.

The U.S. needs to quickly ramp up a domestic battery materials supply chain and use the highest possible proportion of local recycled and raw materials to meet the country’s electrification and clean energy goals, Redwood CEO J.B. Straubel, told members of the U.S. Senate Energy and Natural Resources Committee during a hearing in April on critical mineral shortfalls in the U.S.

Globally, demand for lithium-ion batteries is projected to grow by more than 500% to meet rapid electrification of transportation and the increased need to store intermittent renewable energy. The US needs an end-to-end lithium-ion battery supply chain, he said.

Redwood receives about 6 GWh of end-of-life lithium-ion batteries annually, which equates to about 60,000-80,000 electric vehicles or 20,000 metric tons of material every year for recycling, Straubel told senators.

Redwood has a second plant under development in Reno, Nev., where materials will be recycled and refined to eventually produce 100 GWh a year of cathode and anode components, a company spokesperson told ENR. The cost also is $3.5 billion over 10 years.

The state awarded it more than $105 million in incentives earlier this month, its second-largest such economic development investment, said the Associated Press.

Redwood announced agreements with Ford, Volkswagen Group and Toyota for their end-of-life batteries for its U.S.-based closed-loop battery supply chain.

It also is set to supply Volvo, which is building a battery plant near its South Carolina EV assembly facility, Reuters said, and also Envision AESC, which just announced an $810-million battery plant in Woodruff that will supply BMW EV manufacturing.

The company also said it will supply high-nickel cathode to Panasonic Energy for its battery cells beginning in 2025, it said, when the electronics firm completes construction of an estimated $4-billion battery plant in DeSoto, Kansas, which it announced in July. Redwood said Panasonic also will be the first long-term buyer of its anode copper foil.

Mary B. Powers has reported on engineering and construction issues in the global energy and environmental sectors for more than 30 years from Washington, D.C. and Birmingham, Ala. She formerly wrote for the Platt's group of energy sector publications under McGraw Hill and S&P Global that included Inside Energy and Megawatt Daily, and was state editor for the Lexington, Ky., Herald Leader. Mary has a master’s degree in journalism from The American University.

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

Sponsored Content is a special paid section where industry companies provide high quality, objective, non-commercial content around topics of interest to the ENR audience. All Sponsored Content is supplied by the advertising company. Interested in participating in our Sponsored Content section? Contact your local rep.

On Demand It’s common to see multiple point solutions or environments of a single program management information system being used to manage projects within a program. But this leads to data silos, making it difficult to keep everyone on the same page. Experts will share how they’re successfully managing complex programs within a single platform.

ENR INTERNATIONAL CONSTRUCTION & ENGINEERING SHOWCASE View all Special Ad Sections Archives

Copyright ©2022. All Rights Reserved BNP Media.

Copper Sheet Factory Design, CMS, Hosting & Web Development :: ePublishing